Comprehend the Duty of Foundry Services in Modern Production Solutions

Foundry services have actually come to be indispensable to modern-day production remedies. They give essential parts for various markets, adjusting to the special needs of markets like vehicle and machinery. Advanced casting techniques and automation boost style capabilities while promoting sustainability. As producers seek personalization and on-demand production, these services are evolving. The junction of technology and foundry services questions about future growths and their possible influence on the manufacturing landscape. What adjustments lie ahead?

The Relevance of Foundry Services in Manufacturing

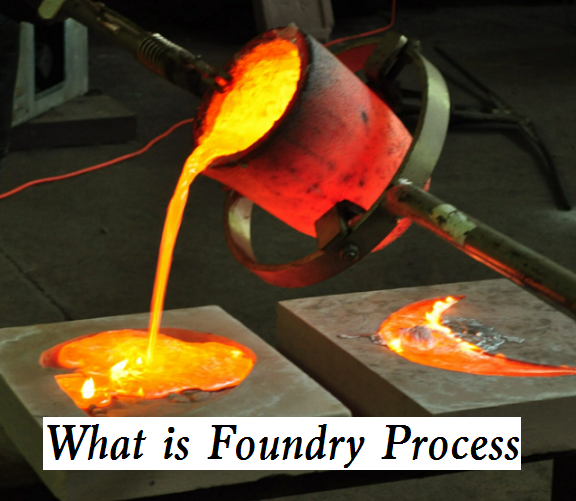

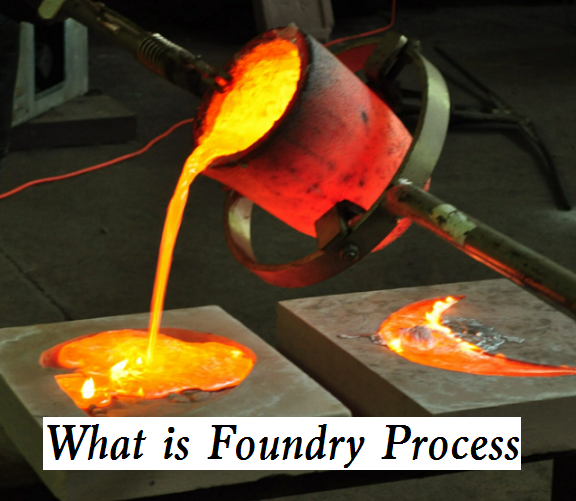

Although often ignored, foundry services play an essential function in modern-day production by offering critical components that develop the foundation of various markets. These services encompass the casting of metals, which permits the creation of intricate shapes and styles that would certainly be tough, otherwise impossible, to accomplish through other manufacturing techniques. Factories create a vast range of products, including automobile parts, machinery elements, and tools, making sure that varied markets can run effectively.

Furthermore, foundry services add to technology by making it possible for customization and rapid prototyping. This adaptability permits suppliers to reply to market needs promptly and efficiently. The foundry sector is significantly concentrating on sustainability, integrating environment-friendly methods that reduce waste and energy intake. By sustaining both standard and advanced production processes, foundry services stay essential, underpinning the advancement of technology and framework in today's economic climate.

Key Technologies Changing Foundry Services

As the manufacturing landscape evolves, numerous crucial technologies are changing foundry services and boosting their effectiveness and abilities. One significant improvement is the assimilation of automation and robotics, which improves manufacturing processes and decreases human mistake. These technologies enable accurate control over spreading operations, improving item consistency.

Furthermore, the adoption of sophisticated products, such as light-weight alloys and compounds, enables shops to satisfy the demands of contemporary industries. Computer-aided design (CAD) and simulation software program likewise play an important duty, helping with faster prototyping and lowering preparations.

Enhancing Efficiency Via Advanced Casting Techniques

To improve efficiency in foundry services, advanced casting techniques are significantly being embraced to optimize manufacturing processes. Techniques such as 3D printing of cores and molds simplify the standard casting workflow, lowering lead times and minimizing product waste. Additionally, accuracy casting techniques, such as investment spreading, permit tighter resistances and complex designs, bring about enhanced item quality.

The assimilation of computer-aided design (CAD) and simulation software application further improves these procedures by enabling shops to predict casting actions, determine possible defects, and make needed changes before physical production. This aggressive approach not only reduces prices but likewise boosts the general integrity of find out this here the cast elements.

Hot isostatic pressing (HIP) modern technology is obtaining traction, consolidating materials and eliminating problems, which results in denser and extra durable products. Collectively, these advanced techniques significantly contribute to the effectiveness and efficiency of modern-day foundry services, positioning them at the forefront of producing innovation.

Cooperation and Supply Chain Combination in Foundry Services

Cooperation and supply chain combination play a pivotal duty in improving the efficiency of foundry services, particularly in a progressively affordable manufacturing landscape (Aluminum Foundry). The alignment of different stakeholders, consisting of manufacturers, consumers, and providers, cultivates a streamlined procedure that improves interaction and reduces preparations. By sharing information, partners can prepare for demands, enhance supply levels, and alleviate risks connected with supply chain disturbances

Integrating sophisticated innovations, such as information analytics and cloud computer, facilitates real-time cooperation, enabling foundries to respond quickly to market adjustments. This harmony not only enhances efficiency however additionally drives technology, as joint efforts cause the growth of brand-new products and procedures customized to specific customer needs. Ultimately, efficient partnership and supply chain combination equip foundry services to provide top notch items successfully, making certain consumer satisfaction and maintaining an one-upmanship in the ever-evolving production read this post here field.

Future Fads in Foundry Services and Their Influence On Production

Arising patterns in foundry services are poised to significantly reshape the manufacturing landscape, especially as markets progressively adopt automation and digitalization. The integration of advanced modern technologies such as expert system and artificial intelligence will certainly enhance the effectiveness of foundry procedures, enabling real-time information analysis and anticipating upkeep. In addition, the increase of additive production strategies is prepared for to revolutionize traditional processes, allowing for more complex styles and lowered material waste.

Sustainability will certainly likewise play a necessary function, with foundries focusing on environment-friendly methods and recycling initiatives to fulfill governing demands and customer assumptions. As companies focus on agility and responsiveness, the change towards on-demand manufacturing will make it possible for factories to satisfy particular customer needs better. Ultimately, these fads will certainly not just enhance operational effectiveness but additionally foster innovation, placing foundry services as important players in the future of manufacturing.

Regularly Asked Inquiries

What Sorts of Materials Are Generally Utilized in Foundry Services?

Common materials used in foundry services consist of different metals like bronze, light weight aluminum, and iron, along with alloys. Furthermore, sand, material, and various other binding agents are typically utilized in molding procedures to produce intricate shapes.

Just How Do Foundry Services Make Certain Quality Assurance in Manufacturing?

Foundry services assure quality assurance through rigorous testing procedures, material assessments, and adherence to sector standards. They implement advanced technologies and continual tracking, ensuring that the last items satisfy specified demands and client expectations regularly.

What Is the Ecological Effect of Foundry Services?

Foundry services can considerably impact the atmosphere with exhausts, waste generation, and source intake. Nevertheless, developments in technology and lasting practices are increasingly mitigating these results, advertising environment-friendly processes within the manufacturing field.

Just How Do Foundry Provider Manage Style Adjustments During Production?

Foundry services attend to layout modifications throughout manufacturing through collective interaction with customers, implementing dexterous approaches, and using innovative software devices. This flexible approach warranties prompt changes while preserving top quality and effectiveness throughout the manufacturing process.

What Qualifications Should Foundry Service Providers Possess?

Foundry company must possess accreditations such as ISO 9001 for high quality management, ISO 14001 for ecological administration, and industry-specific certifications like AS9100 for aerospace or IATF 16949 for auto to assure compliance and top quality requirements. Precision aluminum casting.

The intersection of modern technology and foundry services raises concerns about future growths and their possible influence on the manufacturing landscape. Often overlooked, foundry services play a crucial function in modern-day production by giving vital parts that form the foundation of various industries. As the production landscape evolves, a number of key innovations are changing foundry services and enhancing their efficiency and capacities. Collaboration and supply chain integration play a critical function in boosting the effectiveness of foundry services, official website particularly in a progressively competitive production landscape. Arising fads in foundry services are positioned to noticeably improve the manufacturing landscape, particularly as industries progressively adopt automation and digitalization.